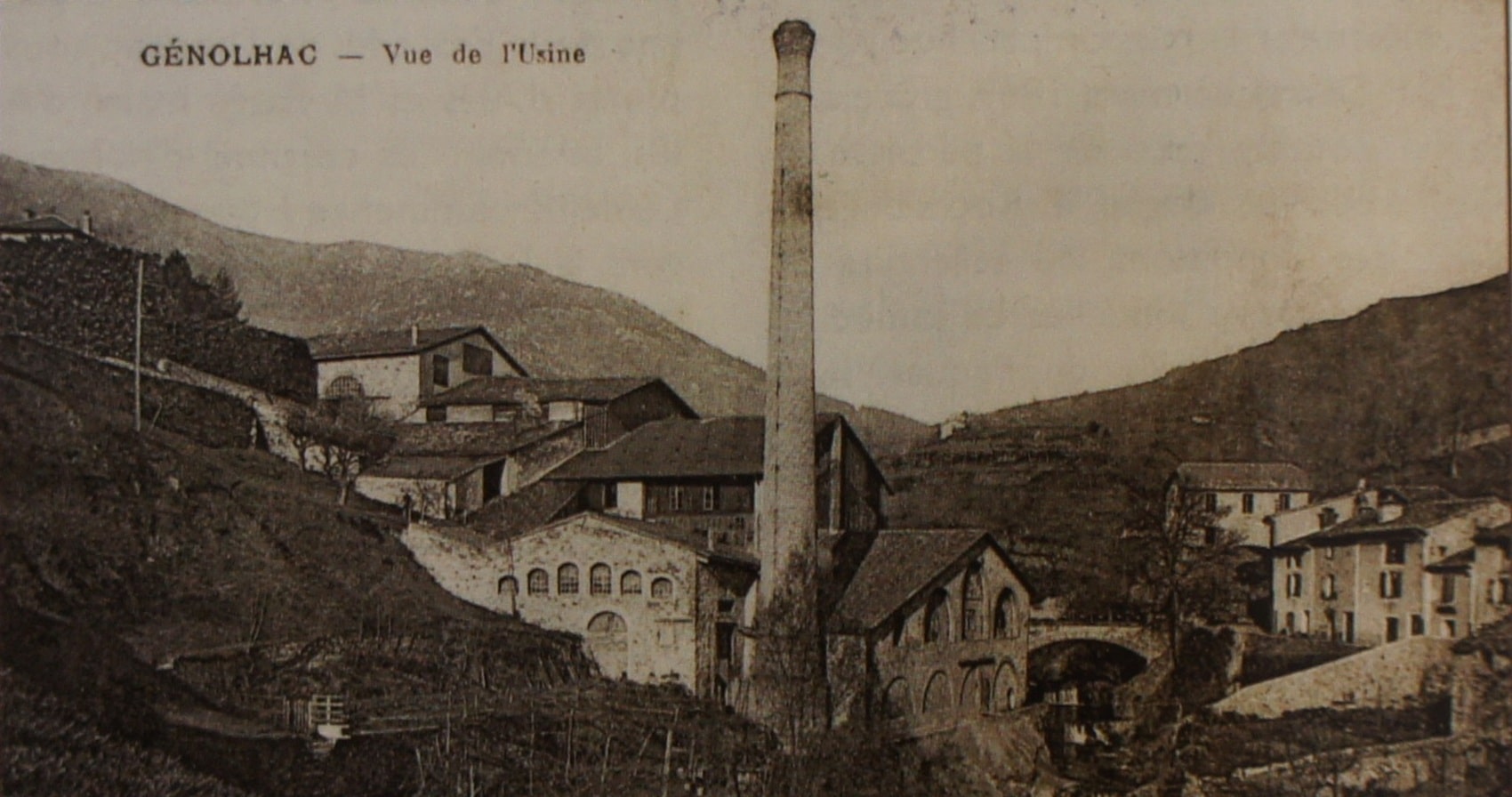

The Tannin Factory of Génolhac |

In 1846, a revolution began in the industry with the discovery of a process for extracting tannins from chestnut wood. It is in this context that the chemical industry took root in the chestnut-producing regions, particularly in Génolhac, where the Ausset-Hermet factory was established in 1847.

In 1846, a revolution began in the industry with the discovery of a process for extracting tannins from chestnut wood. It is in this context that the chemical industry took root in the chestnut-producing regions, particularly in Génolhac, where the Ausset-Hermet factory was established in 1847.

Paul Hermet, a banker from Nîmes, invested in this new venture, partnering with Ernest Ausset, a druggist managing the sale of products in the area. The Génolhac factory stands out as one of the very first industrial facilities dedicated to the extraction of tannin from chestnut wood, which comes from the Cevennes forests, often sold by its owners due to low productivity or poor health.

Paul Hermet, a banker from Nîmes, invested in this new venture, partnering with Ernest Ausset, a druggist managing the sale of products in the area. The Génolhac factory stands out as one of the very first industrial facilities dedicated to the extraction of tannin from chestnut wood, which comes from the Cevennes forests, often sold by its owners due to low productivity or poor health.

Chestnut wood has remarkable characteristics. The tannins it contains are highly sought after in various fields; rich in polyphenolic compounds, they find applications in the leather industry for tanning. These tannins possess antifungal and antibacterial properties, ideal for certain cosmetic applications.

In the wine world, the tannins from the chestnut contribute to the structure and complexity of wines. Used to preserve wood against insects and decomposition, the tannins paired with aesthetics make them a preferred choice in outdoor constructions. Tannin extracts are also suitable for creating natural dyes, providing earthy hues to various textiles.

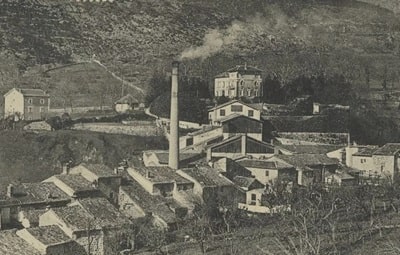

In 1866, the Villa Hermet, residence for the factory managers, was erected and recently acquired by individuals who offer guest rooms.

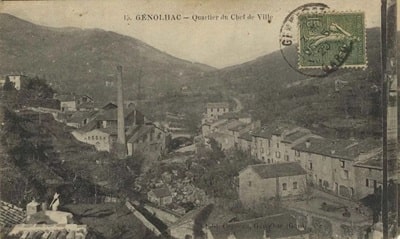

The opening of the railway line in 1867 would soon transform Génolhac. As a result of railway expansion in France, it facilitated the evacuation of production and improved connections between this rural area and urban centers.

Now, local products, especially tannin, can be more easily transported to the train stations, thereby fostering the development of the local economy. This new access also attracts many investors, energizing trade and creating new job opportunities.

Now, local products, especially tannin, can be more easily transported to the train stations, thereby fostering the development of the local economy. This new access also attracts many investors, energizing trade and creating new job opportunities.

Due to its success, the factory even came under the spotlight during the Exposition Universelle in Paris in 1889. However, in 1964, the rise of synthetic products slowed down production, leading to the closure of the factory. Three years later, a rehabilitation project aimed at converting it into a plastic production factory faced community opposition.

In 2002, the municipality of Génolhac purchased the factory with the goal of considering its preservation. Efforts were made to secure the site.

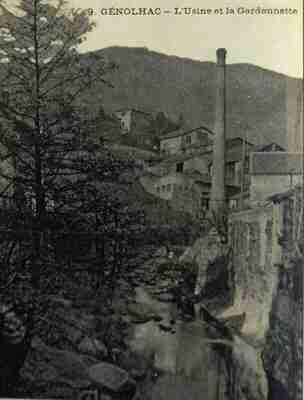

The operation of the factory relies on a hydraulic power system. Water from the Gardonnette, captured upstream, feeds into reserve basins. This production method is both efficient and environmentally friendly, allowing for a reduction in dependence on fossil fuels.

The turbines, which draw their energy from the movement of the water, then get to work. The wood, once received on a platform, is cut into small chips, then immersed in hot water to extract the tannin, which is then stored in tanks before being transported in barrels via a cooperage associated with the factory. The barrels, which are crafted with great skill, are essential for the aging of wines and spirits, each piece being unique and made with traditional techniques.

The turbines, which draw their energy from the movement of the water, then get to work. The wood, once received on a platform, is cut into small chips, then immersed in hot water to extract the tannin, which is then stored in tanks before being transported in barrels via a cooperage associated with the factory. The barrels, which are crafted with great skill, are essential for the aging of wines and spirits, each piece being unique and made with traditional techniques.

Finally, the tannin is also transformed into powder by the Kesner machine before being shipped in bags. It then finds valuable uses in leather treatment, as well as in various industrial applications, all transported by rail or road.

The workers, often recruited from the local residents, played an essential role in the factory's operation. They engaged in various tasks: from cutting wood to processing it into chips, including handling boilers and turbines. This required solid physical condition and good endurance, especially in the face of sometimes rudimentary and strenuous machinery.

The workers, often recruited from the local residents, played an essential role in the factory's operation. They engaged in various tasks: from cutting wood to processing it into chips, including handling boilers and turbines. This required solid physical condition and good endurance, especially in the face of sometimes rudimentary and strenuous machinery.

Despite the importance of their work, conditions were not easy. Many workers labored long hours, often six days a week, with few breaks and modest pay. Workplace safety was not a priority, and accidents were not rare, nor were illnesses related to exposure to the chemicals used in the extraction of tannins.

The factory, due to its importance to the local economy, was able to offer a certain level of stability. However, it was not uncommon to hear stories of families struggling to make ends meet, due to the precariousness inherent in this type of industry.

Over the years, with the rise of technology and the opening of new railway lines, expectations regarding working conditions began to evolve. Strikes and demands for better working conditions became more frequent. Ultimately, while the factory in Génolhac is an example of industrial dynamism, it also remains a symbol of the workers' struggles for rights and decent working conditions.

Former holiday hotel with a garden along the Allier, L'Etoile Guest House is located in La Bastide-Puylaurent between Lozere, Ardeche, and the Cevennes in the mountains of Southern France. At the crossroads of GR®7, GR®70 Stevenson Path, GR®72, GR®700 Regordane Way, GR®470 Allier River springs and gorges, GRP® Cevenol, Ardechoise Mountains, Margeride. Numerous loop trails for hiking and one-day biking excursions. Ideal for a relaxing and hiking getaway.

Copyright©etoile.fr